Two steps forward, one (exploding) step back. October 25, 2009

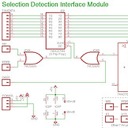

In the past couple of weeks, I managed to do a little more work on the soda machine hack. With the hardware to interface 110VAC relays to 5VDC logic done, the next step is to create a means of connecting it to the TINI390 board. This has turned out to be a little more complex than I’d anticipated, specifically because I don’t have direct access to the various I/O pins (at least not through its Java VM). The TINI is set up more like a microprocessor than a microcontroller; all the I/O is done by reading from and writing to specific memory locations, divided into several pages. The board has only eight general-purpose I/O pins, but it has a twenty-bit address bus and five usable “Chip Enable” pins. All communication with the on-board peripherals (such as the flash memory and probably the Ethernet) is carried over the same data pins, so anything I attach needs some capability to decode addresses in order to avoid reading or stomping on unrelated stuff.

(more…)